We’re back at METSTRADE

Sta-Lok Terminals Ltd. are thrilled to be back exhibiting at the METSTRADE show this year. Held at the Rai Amsterdam...

Stainless steel wire rope is made up of individual wires spun into a strand and has many different wire rope properties and benefits. A number of outer strands are closed over a central core. The number of strands around this core gives different construction of wire their unique characteristics.

Stretch is characteristic of all wire ropes. Construction stretch is caused by the adjustment of wires and strands within a wire rope. When load is first applied to a wire rope, the individual strands bed in, this settlement leads to elongation, referred to as permanent construction extension (Constructional Stretch). This results in a permanent stretch and increase in length and varies depending on the initial build of the wire rope, such as the diameter, construction and lay length.

The elastic extension of the wire rope (Elastic Stretch) occurs when a load is applied to the end of a rope. “Hookes Law” defines that this stretch is proportional to the load applied, i.e stress is proportional to strain. This applies as long as the yield point is not exceeded, after which permanent deformation takes place. If the yield point is not exceeded, elastic stretch can be fully recovered once the applied load is released, meaning the wire rope will typically return back to its normal length.

The modulus of elasticity or resistance to stretch for wire rope will vary upon the wire rope construction. The following stretch calculation can be used as a guide. There are different international standards for calculating the Modulus of Elasticity (E), this should be verified by your structural engineer.

Elastic Stretch = W x L / E x A

Where:

W= Applied Load (kN)

L – Cable Length (mm)

E = Strand modulus of elasticity (kN/mm2)

A = Cross section area of wire rope = Π r²

Where r = diameter of rope/2.

If the stretch is critical in the application of the rope, constructional stretch can be eliminated through the process of pre-stretching or pre-stressing. This is when a load is first applied to the wire rope during the manufacturing or swaging process, and the individual strands bed in; this allows the wire to settle under load prior to installation. This settlement leads to elongation, referred to as permanent construction extension, which can be done before the wire rope gets installed.

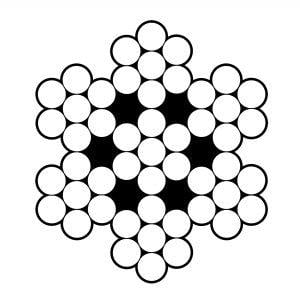

The 1×19 construction is suitable for all types of general applications due to its low elasticity and high breaking load. 1×19 refers to the construction of the wire rope. This is where 19 strands of wire are twisted to form 1 strand. 1×19 is one of the more popular constructions and is typically used for yacht and sailboat rigging, balustrading and architectural projects.

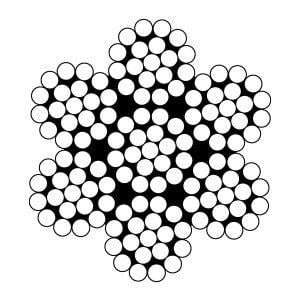

Compacted Strand wires feature high strength and very low stretch, providing this wire with excellent longevity and performance. A compacted strand consists of a normal inner core but a compacted outer core. This is when the rope has undergone a specific process during manufacturing where the outer strands are compressed, resulting in a thinner diameter overall but increased strength. Compacted strand wire rope is commonly used when there is heavy lifting involved requiring high breaking loads and/or repetitive bending when lifting. Due to the tightly compacted strands, this does mean the rope offers some corrosion-resistant quality making it easier to inspect and reducing the risk of wire breakages and making them longer lasting.

The 7×7 construction wire provides high flexibility due to the thinner strands of wire. This construction is made up on 7 strands twisted together to form 1 strand, which is then joined by 6 more of these. The 7×7 rope uses thinner strands but over double the number of strands than the 1×19 rope, but the end size is still the same diameter. Some common uses include guardrails, standing rigging, and marine yacht and sailboat rigging.

The 7×19 construction is the most flexible of the multi-strand wire ropes. This construction consists of 7 strands, each containing 19 wires twisted together to form a single strand which means it has over 2.5 x the total number of wires than the 7×7. Due to the thinner construction of the wire rope, it does mean it has greater flexibility but also lower breaking loads meaning it isn’t as strong as the 7×7 or 1×19. As a result, the 7×19 is suitable for most running loads, garage door cables, gymnasiums, general engineering applications or when the cable is required to run over a pulley.

Found where a covering is needed for functional or aesthetic purposes. PVC coated wire is stainless steel wire rope covered in PVC for added durability for uses in more aggressive environments where added protection is needed, such as soils, salt water and acidic water. The PVC as standard come in white but can also come in other colours should the cables be needed for aesthetic purposes.

As a leading UK supplier of stainless steel wire rope, Sta-Lok distributes a wide variety of sizes and constructions from a dedicated UK warehouse. To find out more about Sta-Lok’s supply of stainless steel wire rope. Contact us today. To find out more about Sta-Lok’s wire rope and the benefits of using it, download our wire rope brochure here.

We believe that customer service is an extension of the quality products we produce.

Our technical specialists are on hand to assist with any product or technical queries, or indeed, bespoke or unique requests to help you complete your project.